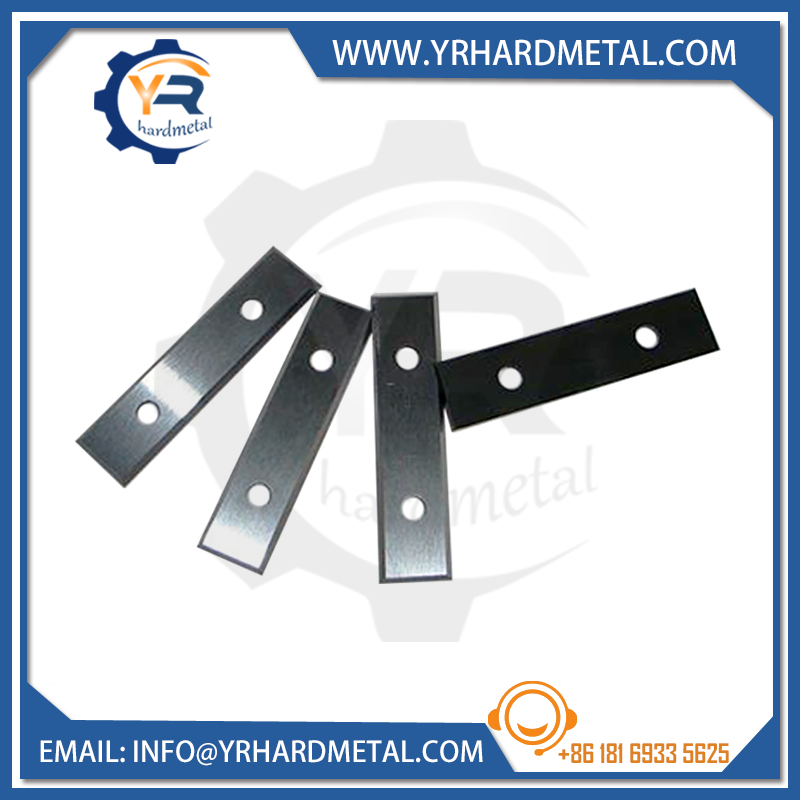

Tungsten Carbide inserts for Woodworking

| Advantage | Insert very sharp, wear-resistant, suitable for a variety of woodworking machine tools, can process all kinds of bamboo products and wood products, superior performance, long service life, cost-effective |

| Application | Suitable for furniture, wood line, picture frame, handicraft, toys, decoration line, wood floor, doors and windows and other bamboo products and wood products. Applicable models: single axis milling machine, router, wood thread machine, plane plane, press plane, double plane, four plane and other woodworking machines. |

Product information:

- select appropriate cutting amount

- The cutting speed of different materials is very important for the service life of tools and the quality of material processing.

- High speed cutting can be used for general materials. For harder materials and tools with larger tool diameter, it is better to use low speed cutting and slow down the feed speed. The feed speed shall not be fast or slow on average, and shall be smooth during feeding. If there is a stop in the cutting process, it will burn the tool and greatly reduce the service life of the tool.

- The cutting speed depends on the following three aspects: A. machining materials; B. types and specifications of cutting tools; C. equipment.

- If the tool with larger diameter is used, it can be processed by several times of feeding, which can improve the service life of the tool and make the operation safer. The tool with larger diameter usually uses high-quality desktop equipment.

III. tool maintenance

- Maintenance of cutter body

(1) keep the cutting tools clean. After use, remove the resin, sawdust and other dirt from the wood. Use standard industrial solvent to clean the cutting tools.

(2) apply a small amount of oil to prevent rust on the surface of the tool, and clean all stains on the tool handle, so as to prevent slippage in the use process.

(3) do not regrind the tool and change the shape of the tool without permission, because each grinding process requires professional grinding equipment and professional grinding skills, otherwise it is easy to cause edge fracture and accidents.

Contact Us Please call us or email us info@yrhardmetal.com to discuss your requirements.